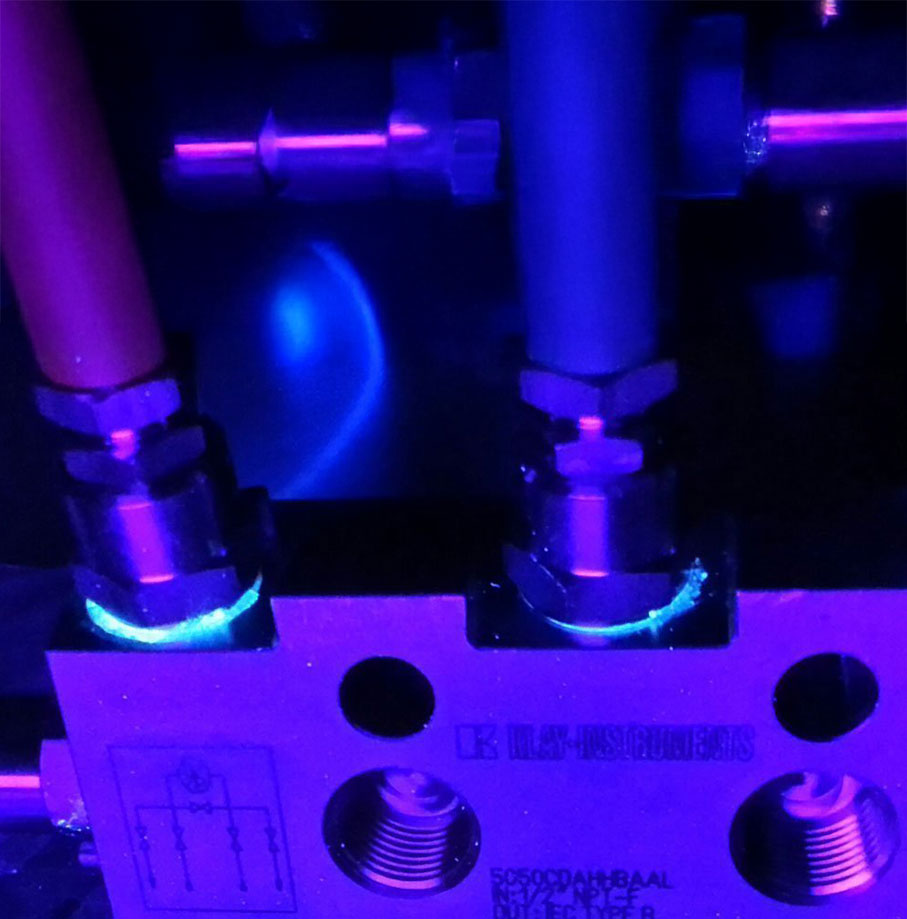

Oxygen clean

O₂ clean room

Request advice now

After submitting the form, you will receive a confirmation. We will contact you shortly with personalised advice.

Clean room services

Complete cleaning, testing and certification

Our specialists are ready to assist you. Do you have questions about overhauls, sales, or maintenance? Feel free to contact us for a fast and reliable solution.